Tank Connection Proprietary Storage Tank Coating System

Date: 03.29.2016

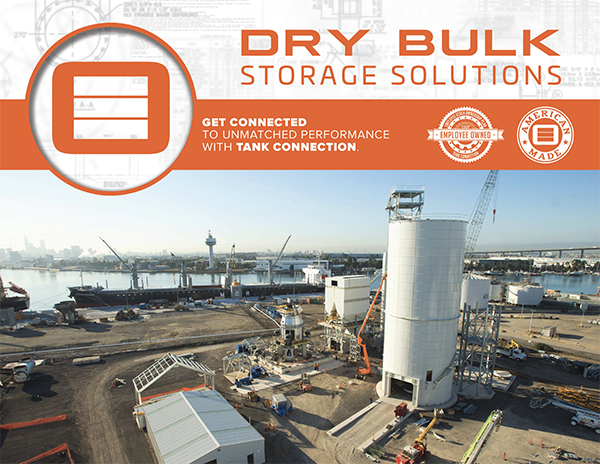

Tank Connection Proprietary Coating System – No Other Bolted Tank Company Can Offer LIQ Fusion 8000 FBE™

So what is so great about Tank Connection’s proprietary LIQ Fusion 8000 FBE™coating system? Just review the data provided in controlled lab testing and you will quickly note that this coating system outperforms ALL coating systems in water storage applications. It has the best performance data and is a stronger system than vitreous/glass enamel in liquid storage applications, which use to be the top performance coating. LIQ Fusion 8000 FBE™ is available exclusively through one company, Tank Connection.

The superior performance of advanced powder coating systems is recognized in the water industry. We have a growing number of clients that prefer Tank Connection’s LIQ Fusion 8000 FBE™ coating system over any system available for water storage. Even other suppliers of vitreous/glass enamel are now promoting all types of powder coatings for water storage. The answers are simple, high performance fusion powder coatings will outperform their enamel coatings.

It is important to remember that glass/vitreous enamel coatings cannot be recoated in the future, only replaced. Powder coated tanks and field-welded tanks with field-applied coatings can be recoated in the future, which allows for permanent water storage facilities that are not limited in service life. When the edges or bolt holes on glass tanks start to rust, it can’t be stopped. These areas will rust and continue to rust. Tanks coated with vitreous/glass enamel in its poorest form become throw-away, disposable tanks, similar to today’s household appliances. The industry is waking up to performance products that are designed to stand the test of time. The best powder coating systems are available and their performance is unmatched.

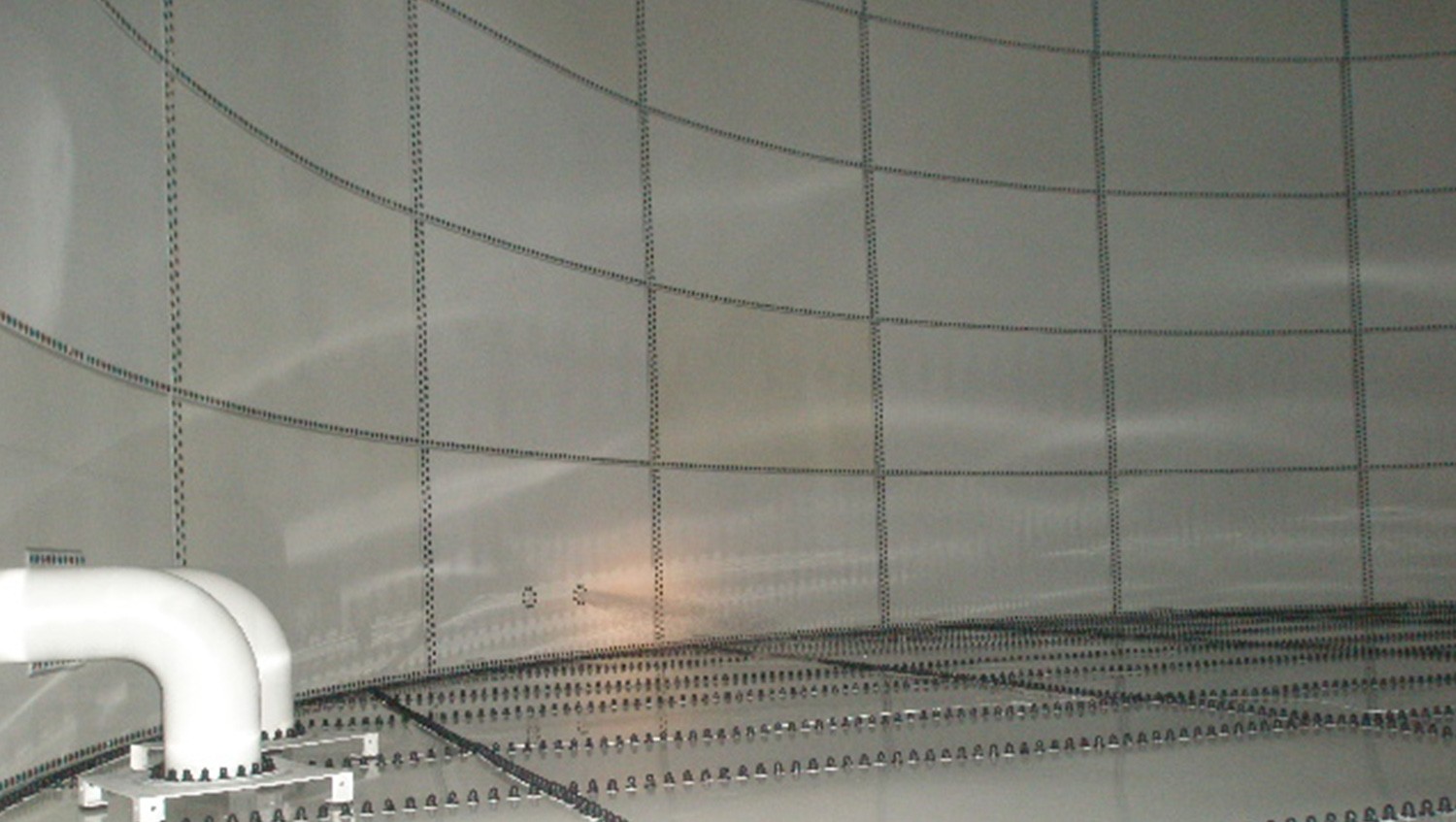

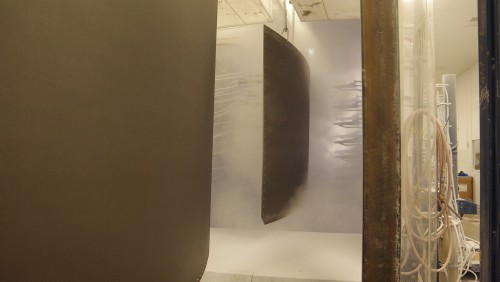

LIQ Fusion 8000 FBE™ is applied on blasted steel substrate surfaces utilizing a multi-million dollar process application, similar to high quality powder coatings systems utilized in the automotive industry. Between our proprietary coating formulation and the coating application process offered, Tank Connection does not have a close “second place” contender in the industry. We compete with suppliers that use an “easy bake” oven to cure coatings and others that don’t even blast their steel prior to coating their steel. Really? As a benchmark standard for quality, we consider some of these products nothing less than junk, but there is never a shortage of uninformed buyers. Based on the volume of storage tanks we supply, we operate at true economies of scale, offering highly superior products competitively priced with suppliers of inferior products. Yes, we offer the best in water storage tanks for less.