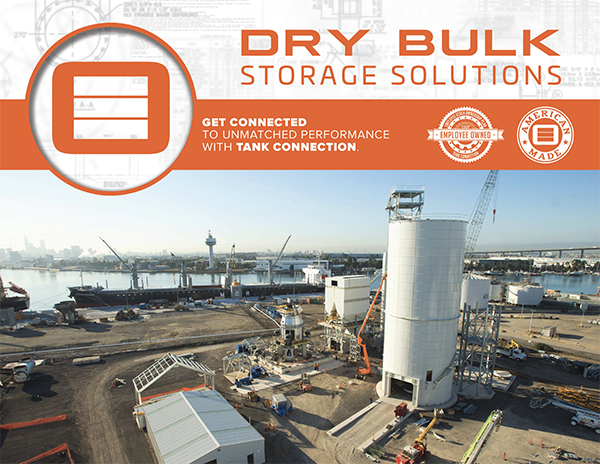

Tank Connection Covers

10/07/2022 · 8:16pm

Tank Connection's growing line of premier aluminum tank covers take product protection to the next level. Tank Connection Covers feature enhanced design and manufacturing methods that provide increased flexibility and strength.